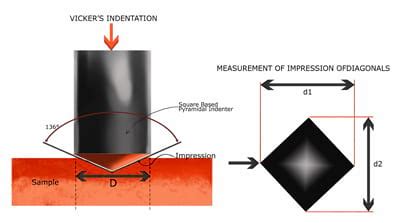

vickers hardness test is measured using what parameter|vickers hardness of common materials : suppliers The Vickers hardness test or the 136 degree diamond pyramid hardness test is a microindentation method. The indenter produces a square indentation, the diagonals of .

webCHEVROLET S10 Usados, seminovos e Novos em MG. 1 - 50 de 1.235 resultados. Tipos de anúncio. Ordenar por +13. Patrocinado. 19. Chevrolet S10 2023 2.8 16v turbo diesel lt cd 4x4 automático . Juiz de Fora, São Sebastião. Adicionar aos favoritos +2. 8. S10 2.8 diesel interculer 2003. 249.000 km; Prata; 2.0 - 2.9; Pick-up; Aceita trocas. R .

{plog:ftitle_list}

WEBPela Porta dos Fundos. Brasileirinhas apresenta o filme “Pela porta dos fundos” .

The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 .

The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials irrespective of h.Vickers hardness testing is vital in assessing critical parts' hardness and wear resistance, such as engine components, gears, and turbine blades. This ensures the reliability and safety of these components under extreme operating .

A method that can be used for figuring out a material’s hardness—a measurement of its resistance to deformation in the presence of force—is the Vickers hardness test. While it finds .

Originally developed by the Vickers Company of the United Kingdom in the 1920s to test alloy armor plates, the Vickers Hardness Test is still utilized to evaluate welded joints and heat-affected zones (HAZ) of metal .The Vickers hardness test or the 136 degree diamond pyramid hardness test is a microindentation method. The indenter produces a square indentation, the diagonals of .The Vickers Hardness (HV) is calculated by optically measuring the diagonal lengths of the impression left by the indenter. The measurements are converted to HV using a table or formula. Load range: From 10 gf up to 100 kgf. Play. How .

In Vickers hardness testing, a square pyramidal diamond indenter with specified face angles is used (see figure below). After the pyramidal diamond tip (indenter) is pressed into the test sample at a perdetermined load (F [N]), the indentation .The Vickers method has a test load range from 1 gf according to ISO respectively from 1 gf up to 120 kgf according to ASTM, which means that this method can be used for hardness testing across all load ranges (from the micro to the low .Vickers hardness test is also known as the diamond pyramid hardness test which employs a diamond pyramid indenter and variable loads ranging from 1 to 120 kg. The Vickers hardness .

Vickers hardness measurement is a technique used to measure the hardness of a material and compare it to other materials by using a Vickers hardness number. . the Vickers hardness data measured at room temperature are plotted against the Δ M k ¯ parameter [3], . Specimens randomly selected and submitted to a Vickers hardness test with a . 1. Macrohardness testing Macrohardness testing measures the hardness of a material on a larger scale under heavy loads, typically over 1 kg or about 10 newtons (N). Inspectors use this test for materials and samples that . In order to use this law, the hardness values have to be measured using consistent hardness test parameters. Martinez Salazar et al. [ 15 ] measured hardness over 6 s using two loads: 0.25 and 0.5 N. Using this input information along with data from Table 1 , the estimated hardness is 81 MPa at a load of 0.25 N and is 80 MPa at a load of 0.5 N . Hardness of acrylic resin (VIV), composite resin (ORT) and porcelain (POR) denture tooth materials was measured using a traditional Vickers hardness (HV) method and Martens hardness (HM) method at 2, 10 and 50 N test loads.Vickers hardness was also calculated from the force-indentation depth curves (HVfid) that were recorded during Martens .

The two measurements are converted into a Vickers hardness (H V) value using the following equation: H V = 0.1891 * {F[N] / d1[mm] * d2[mm]} Sample Preparation. For a high-accuracy measurement, the test should be performed on a flat specimen with a polished or prepared surface. The quality of the required surface is dependent on the force used.How to use the Vickers hardness test for a wide range of applications, including micro hardness testing. . For the Vickers hardness test, the measured diagonals should not deviate more than 5.0% from each other. For the Knoop hardness test, the two halves of the long diagonals must not differ by more than 10.0% from each other.

vickers microhardness test procedure

The general principle of the Vickers hardness test, defined by ASTM E-384, is based on an optical measurement system. The Vickers hardness test can be a micro indentation test and also for the macro hardness test. It is mainly divided into two steps. . The surface should be polished in the way that the parameters and the tip of the .The Vickers hardness test can measure a wide range of hardness values, from very soft materials to extremely hard ones. This makes it suitable for testing materials with a wide range of mechanical properties, including those used in aerospace, automotive, and construction industries. . Once the test parameters are set up correctly, the test .There are different scales to measure hardness, including Brinell hardness, Rockwell hardness, Meyers hardness, and Vickers hardness test. The Vickers hardness scale, named after the company where it was developed in 1921, is the focus of this article. This test is an alternative to Brinell hardness, and it is relatively easier to use because .Vickers Hardness Test. The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for small parts, thin sections, or .

gas analyzers device

Also, the Vickers tester measures hardness by the Vickers Hardness Value (symbolized as HV) or the Diamond Pyramid Hardness Value (or DPH). Another unique feature in Vickers tester is the usage of two unique parameters. A. Macro Hardness – These Vickers testers use loads ranging from 1kg to 100 kg. They are specifically designed to test hard .3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually apply the specified load using the machine.The load should be maintained for a predetermined dwell time, usually between 10 to 15 seconds.

Technical Parameters. Hardness (H): It could be measured by either Mohs scale, Vickers scale, Rockwell scale or Brinell scale. . Understanding Vickers’s Hardness Test. I use Vickers’ Hardness Test which can be used across different materials thereby enabling me identify material’s level of brittleness.This involves pressing the diamond .

different types of gas analyzers

vickers hardness test procedure

In order to use this law, the hardness values have to be measured using consistent hardness test parameters. Martinez Salazar et al. [ 15 ] measured hardness over 6 s using two loads: 0.25 and 0.5 N. Using this input information along with data from Table 1 , the estimated hardness is 81 MPa at a load of 0.25 N and is 80 MPa at a load of 0.5 N . Vickers Hardness Test. The Vickers hardness test involves the use a 4-sided square-based pyramid indenter, with a precisely defined constant force on the test specimen to evaluate the surface area of the indentation. .The Vickers method is based on an optical measurement system. The Microhardness test procedure, ASTM E-384, specifies a range of light loads using a diamond indenter to make an indentation which is measured and .

In materials science, hardness (antonym: softness) is a measure of the resistance to localized plastic deformation, such as an indentation (over an area) or a scratch (linear), induced mechanically either by pressing or abrasion.In general, different materials differ in their hardness; for example hard metals such as titanium and beryllium are harder than soft metals such as .

2. Vickers Hardness Measurement The Vickers hardness is evaluated by making an indenta-tion on the material to be tested with a specific force using a diamond pyramid-shaped indentor with specific dimen-sions as given in the standards for a specified amount of time. The Vickers hardness (HV) number is then deter-TORSION TESTING SETUP The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers test is often easier to use than other hardness tests since the required calculations are independentThis standard has been approved for use by agencies of the Department of Defense. 1. Scope 1.1 This test method covers the determination of the Vickers hardness of metallic materials, using applied forces of 1 kgf to 120 kgf,2 the verification of Vickers hardness testing machines (Part B), and the calibration of standardized hardness test .

In the Vickers hardness measurement, the combined uncertainty associated with the hardness value takes into account the relative uncertainties of diagonal length (d), the test force values (F) and other parameters like uncertainties in the indenter geometry, the indentation measuring system, etc., which are accounted in the CMC of the machine .

Hardness is a useful measure of a material’s resistance to permanent indentation; but for viscoelastic polymers, hardness data are highly dependent on the test type and the parameter set chosen .The ISO/DIS 14577 Metallic materials - Instrumented indentation test for hardness and materials parameters Part 1-3 (IIT) concerns test forces up to 30 kN. The paper reports on IIT at test forces ranging from 0.002 N to 1000 N on non magnetizable steel X8 CrMnN 18- 18 (1.386) with well polished surface using Vickers indenter and four hardness .

The characterization of materials. R.E. Smallman CBE, DSc, FRS, FREng, FIM, R.J. Bishop PhD, CEng, MIM, in Modern Physical Metallurgy and Materials Engineering (Sixth Edition), 1999 5.2.2.4 Microhardness testing. The measurement of hardness with a microscope attachment, comprising a diamond indentor and means for applying small loads, dates back more than 50 .choice of hardness in the various Vickers IF equations. The usual convention in the hardness community, and the one that is adopted in every formal hardness standard in the world, is to define Vickers hardness (HV) as the load divided by the contact area of the four faces of the indentation. This leads to the standard definition: (4)Difference between, Brinell,Rockwell and Vickers Hardness Test What is Hardness? Hardness is the property of a material that enables it to resist plastic. . A hardness property value is the result of a defined measurement procedure. Hardness of materials has probably long been assessed by resistance to scratching or cutting. An example would . Rock hardness and texture are two dominant factors controlling such engineering characteristics of rocks as drillability, blastability, and machinability. They are also directly responsible for tool wear and operational costs of the drilling operation. In this paper, an attempt has been made to develop some experimental equations for the prediction of these factors .

vickers hardness test explained

Resultado da The Agent Destiny free spins feature starts with 9 free spins. During the feature, each spin calls out Mega Symbols and the excellent Linked Reels .

vickers hardness test is measured using what parameter|vickers hardness of common materials